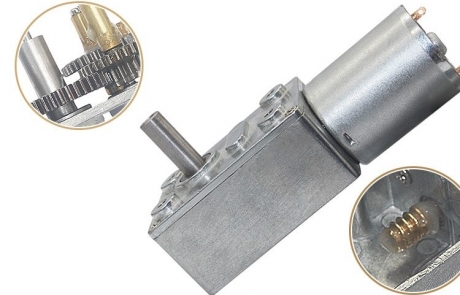

JGY-370 DC Motor

JGY370 Low speed DC motor with worm metal gearbox for high torque application like 4wd arduino robotic car,dc motorized curtains, smart window opener. JGY370 motors are permanent magnet motors known for delivering high power in a compact, portable package. JGY-370 DC motors Ideal for applications requiring motor speed adjustment and reversing capabilities.

Good quality and long lifetime, High torque and Low nosie.

JGY370 worm gear motor has the function of self-locking in power failure. The maximum bearing capacity of the gear is about 30KG.

About quality : High precision all – toothed gears , low noise , zinc alloy die – cast alloy pressure shell , stainless steel hardened Output shaft .

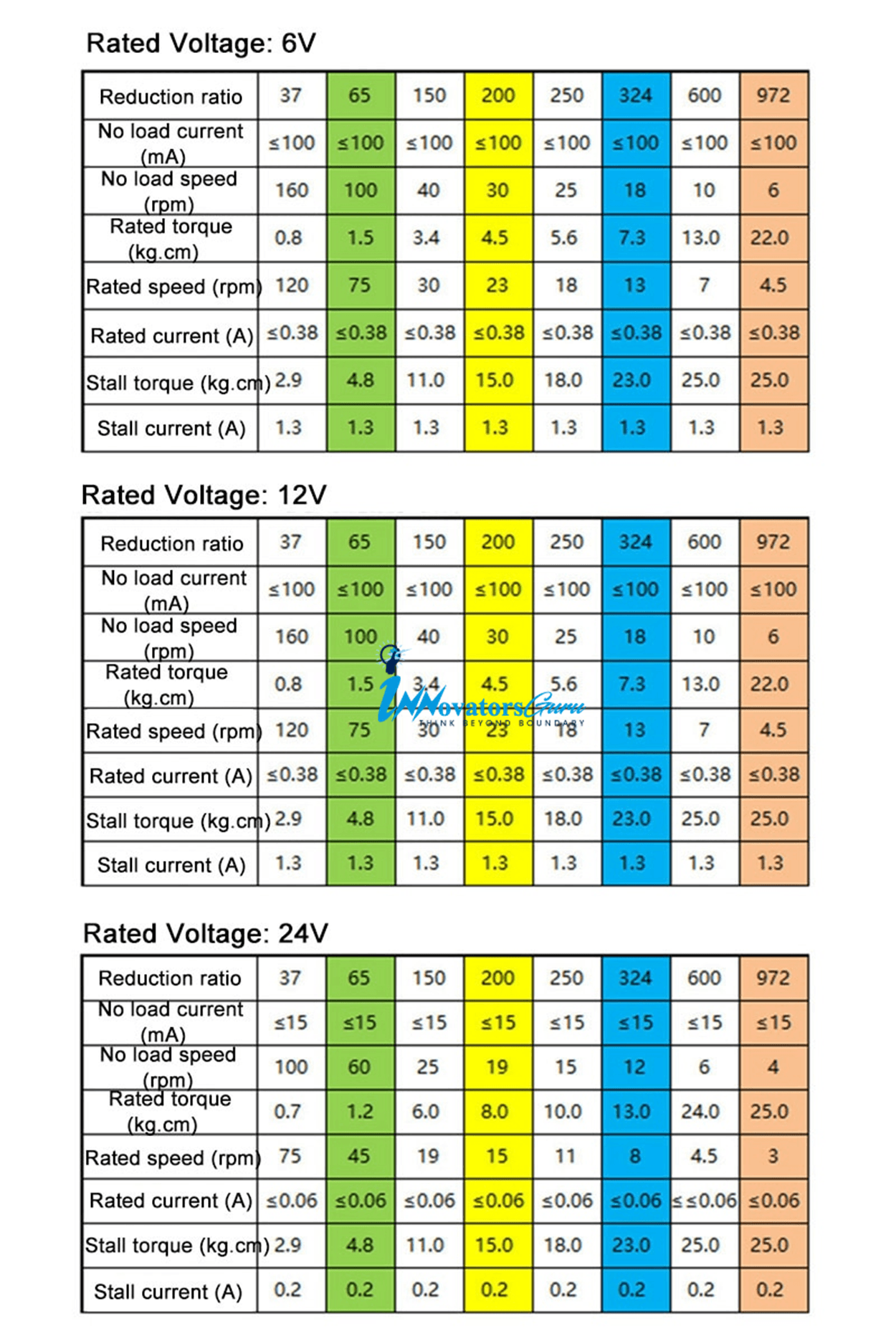

JGY-370 Motor Specification

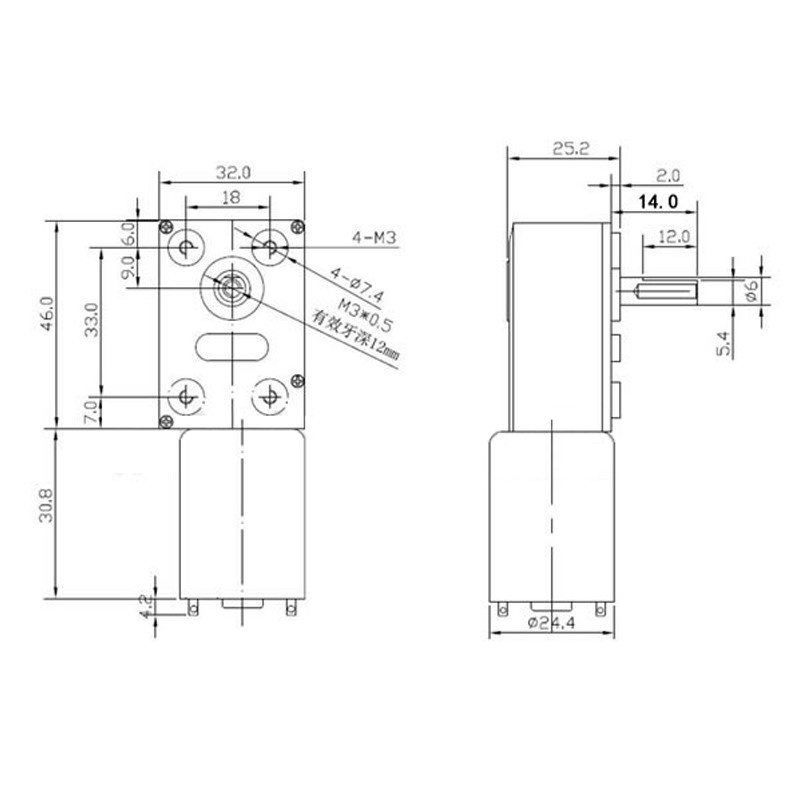

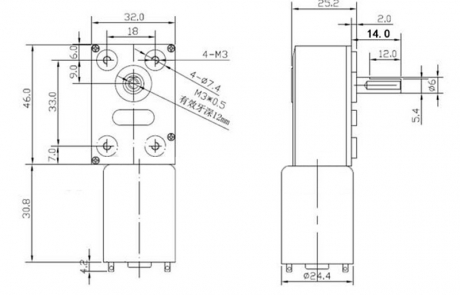

JGY-370 Motor Dimensions

Know More About JGY370 Motor

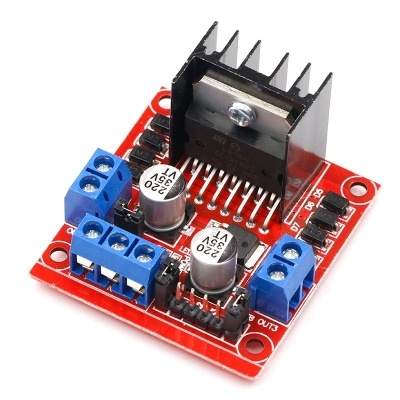

About the motor: Turbo worm deceleration and deceleration, all-metal gears can be used with the speed controller to control the speed (controllable range 0-select

The fixed air speed can be reversed and the motor can be reversed and returned (replace the motor terminal block positive steel plate change positive or negative or match the store speed adjustment

With positive and negative special speed regulator, forward and reverse switch). JGY370 turbo worm motor has a power-off self-twisting function and the largest gear.

The bearing capacity is about 30KG. For the human body parameters, please refer to the following parameter table size circle. If you have doubts, you need more parameter sizes, etc. Please contact

Department of customer service.

JGY-370 Motor Use tolerances

- Pay attention to the range of voltage and current used , use the motor in the case specified in this standard , otherwise

The life of the motor will drop. - Handling the motor: Take it lightly and use the outer casing of the motor as much as possible.

- Motor wiring: The red lead is connected to the positive pole, and the black lead is connected to the negative pole. If the reverse motor is rotated in the opposite direction.

- Overload : Use as much as possible within the load range specified by our company. It is forbidden to block or close the motor.

The state will run for a long time, otherwise the motor will burn out. - Motor Storage : Storage Temperature : 0″C-40″C, Storage Humidity: 15%-90%RH Avoid placing in high temperature, high humidity and corrosive gases.

- Motor usage temperature : 0″C-70″C

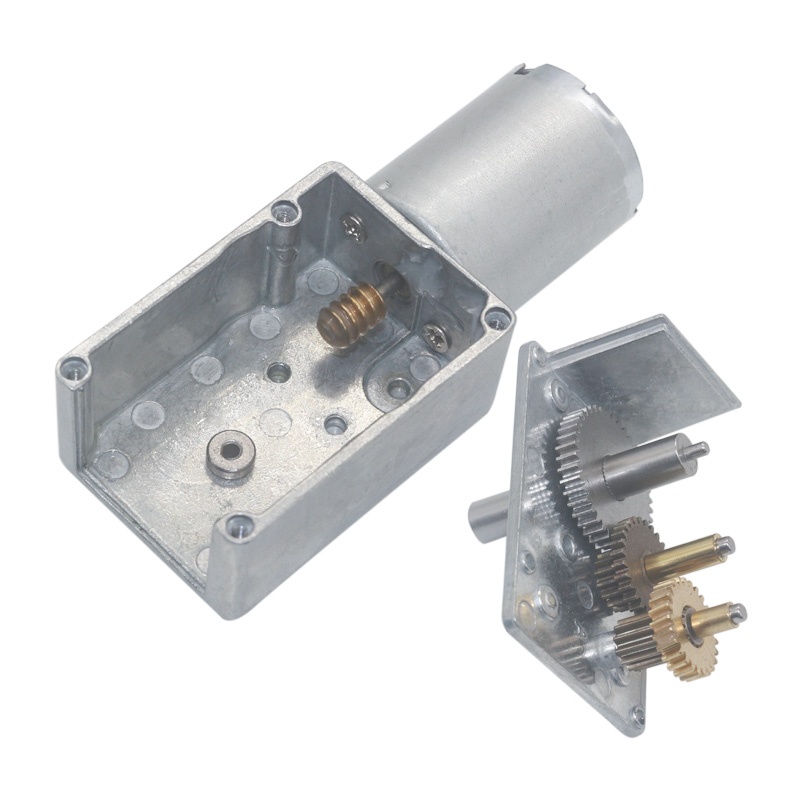

JGY-370 Motor Details

Gearbox:

- High precision all-round gears

- Pure copper worm gear

- Ball precision gear

Outer shell:

- Zinc alloy die-cast alloy pressure shell, stainless steel hardened Output shaft.

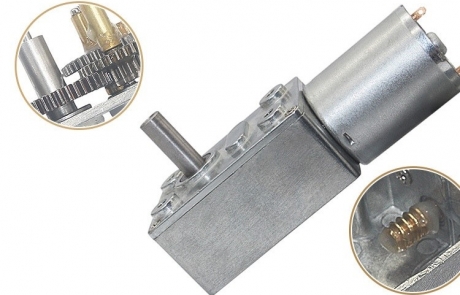

Rotor:

Silver copper nickel commutator and copper wire have super strong electrical conductivity and high-density molecular coating which makes the motor powerful and reliable.

It has a coating layer, which is effective in separating dust, high-temperature resistance and long life.

The Motor rotor is made of pure copper, with low resistance and electrical conduction. the rotor core is made from high-quality strong Silicon steel with low reluctance.

High-quality carbon brush

For Better commutation performance high-quality carbon brush are used which provides

Good thermal conductivity and low friction, the low wear of carbon brushes

this facts directly determines how long the motor can be used.

Field magnet

A high strength magnet with a small volume, lightweight, are provided for, low energy consumption, Strong power, greater torque, etc.

Note: JGY370 deceleration motor has a normal service life of 800 to 1000 hours of continuous rotation and load.

Long time blocking or destructive test is not covered by the warranty. Please slow down the motor to avoid blocking or overloading. Otherwise, the tooth gear loss will occur.

Forward and reverse control is not suitable for gears to switch steering immediately in the transmission, after complete stop Can switch steering

JGY-370 Motor Use Limitations

- When you use the motor, there is no restraint. If the lubricant does not flow through the bearing through the rotating shaft, it will hinder the operation of the motor.

- The rotation of the shaft may have the opposite effect on the life of the motor. For the extension of the life, please check if your load is in accordance with the regulations.

It is not allowed to be overloaded or the end of the shaft is hung with items that hinder the rotation. - Manufactured as an eccentric heavy radiation load, the life of the harmful motor.

- Please do not store in high temperature or extreme humidity for four weeks , please do not place it in corrosive gas , which will reduce the motor effect .

- Do not run the motor in the surrounding high temperature and humidity.

- When soldering the motor terminals of the positive and negative poles of the power supply, the temperature of the soldering iron should be 340″C+40%C, and the heating time should not be within 3 seconds.

Plastic deformation causes the solder point to flow into the motor or break the end of the wire during operation, which can degrade the motor function. - Do not allow the motor shaft to get stuck. When power is transmitted, the motor will be overheated and burned out in a short period of time.

- It is impossible to guarantee the quality of the workman, so that the motor meets the instructions mentioned in the book, or the apparent judgment is obviously a fault.

Quantity - The supply is regulated by electricity, and the reliability is within the measurable requirements.

- Install the pulley or gear without abnormal aggravation when pressing in.

- When the motor is installed, the screw is too long, which will cause contact between the motor itself and the rotor, which will affect the characteristics.

JGY-370 Motor Application

The JGY-370 motors are widely used for

- Household appliances and products,

- Office equipment,

- Health equipment and medical equipment.

- Beauty and fitness equipment,

- High-end toys and gifts,

- Electric tools,

- Automatic window sprayers,

- Robotic cars

- Automated facilities,

- Intelligent home automation systems,

- Industrial automation controls,

- Industrial drive assemblies.

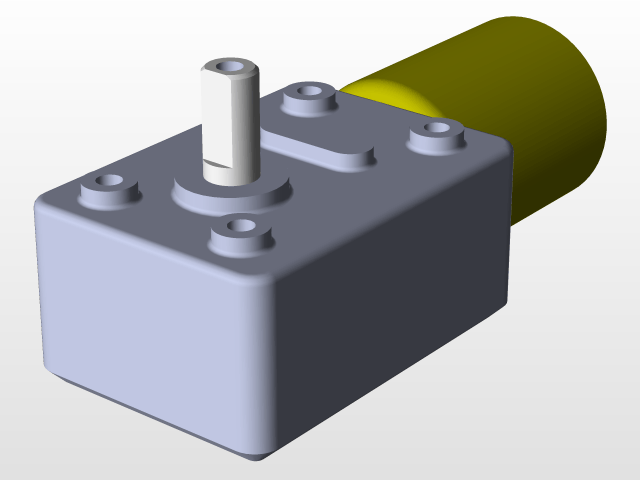

JGY-370 Motor 3D CAD model

3D model from Grabcad is available for download.

Leave A Comment