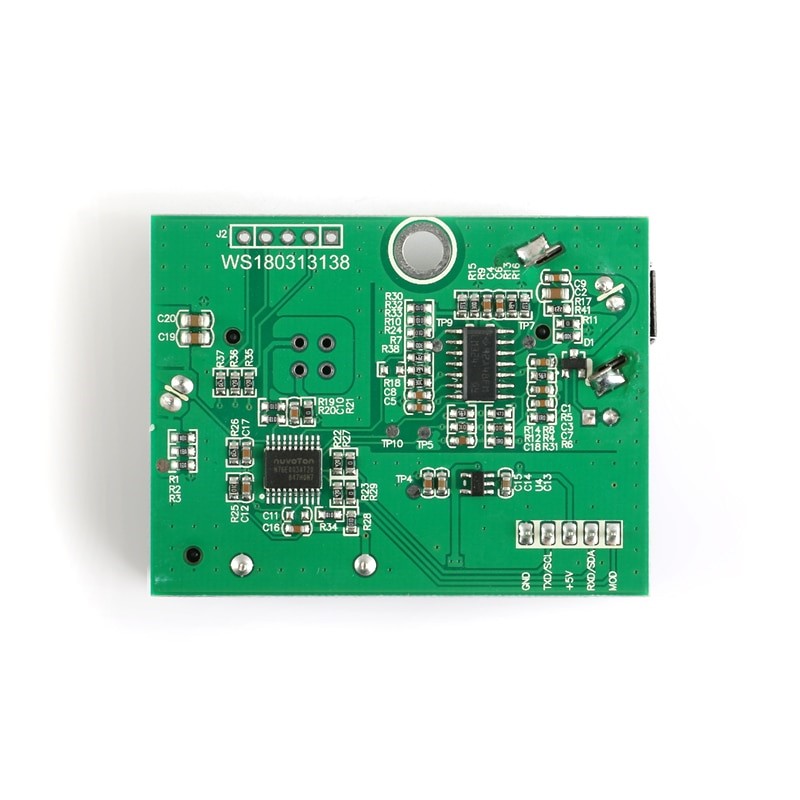

ZPH02 Dust Sensor

Definition – ZPH02 Dust Sensor

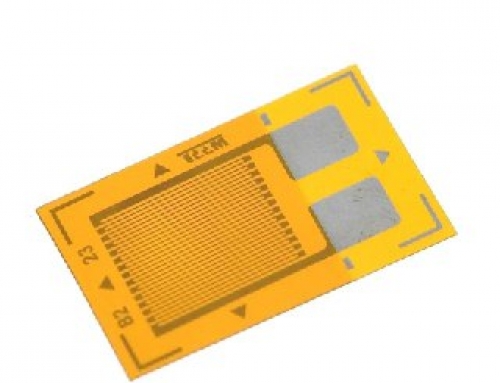

A ZPH02 LASER Dust Sensor uses advanced integrates infrared PM2.5 (Particulate Matter that has a diameter of less than 2.5 micrometers) principle and the more effective VOC detection technology, enabling simultaneous detection of PM2.5 and VOC in the same environment. ZPH02 uses the particle counting principle to sensitively detect dust particles with a diameter of 1 μm.

The VOC sensor has extremely high sensitivity to organic volatile gases. The sensor is aged, debugged, calibrated and calibrated before leaving the factory, with good consistency and high sensitivity. With PWM, UART digital serial interface (customizable IIC interface output mode).

Buy Now Aliexpress | Amazon.com

Applications of ZPH02 LASER Dust Sensor

this Infrared PM2.5 detection technology based gas sensor is widely used in

- Smoke alarms,

- Industrial smoke alarms and

- Portable smoke detection instruments

- environmental monitoring

- Intelligent Integrated ceiling

- ventilator

- Air purifier

- Fresh air system

Features of ZPH02 Dust PM2.5 Sensor

- Long-term stability

- Consistent

- Extremely high sensitivity,

- Excellent long-term stability,

- Factory-calibrated calibration,

- Sensor fault self-diagnosis,

- low power consumption,

- Rich interface output

- Easy to install and maintain

| Specifications | Discriptions |

|---|---|

| Detection ability | smallest particles 1 μm diameter |

| Physical interface: | EH2.54-5P terminal socket |

| Output data: | A signal switching output |

| Operating voltage: | 5.0±0.2V DC (no voltage reverse connection protection) |

| Output data type: | TTL level (built-in 200Ω protection resistance) |

| Working current: | ≤90mA |

| Warm-up time: | ≤1min(device warming-up time) |

| Response time: | ≤ 20 seconds |

| Recovery time : | ≤ 60 seconds |

| Working temperature: | 0~50°C |

| Working humidity: | ≤95%RH |

| Storage temperature: | -30℃~50℃ |

| Dimensions: | 59.5 × 44.5 × 20mm |

ZPH02 Specifications

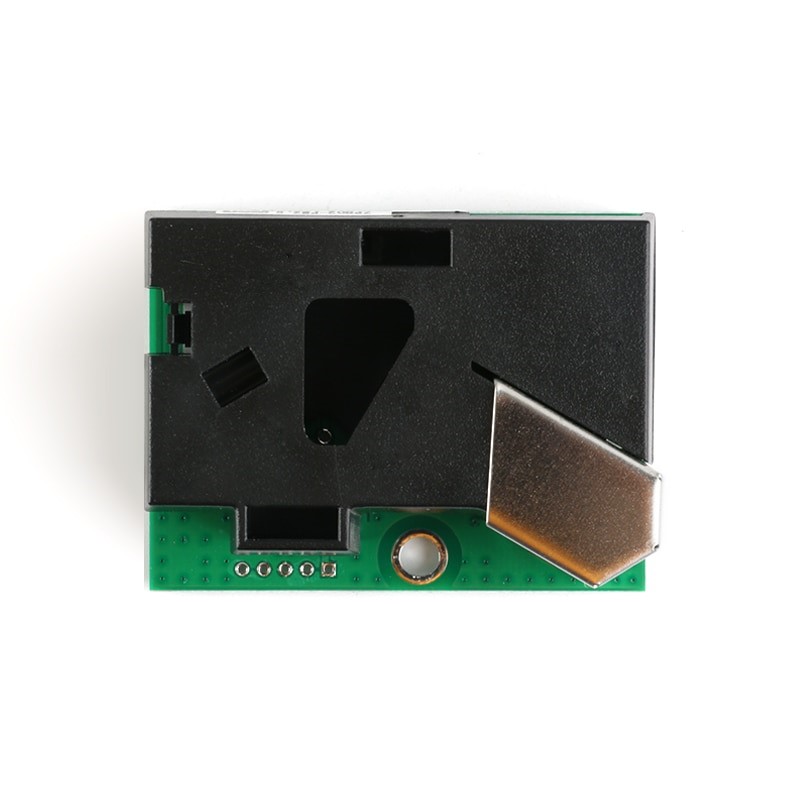

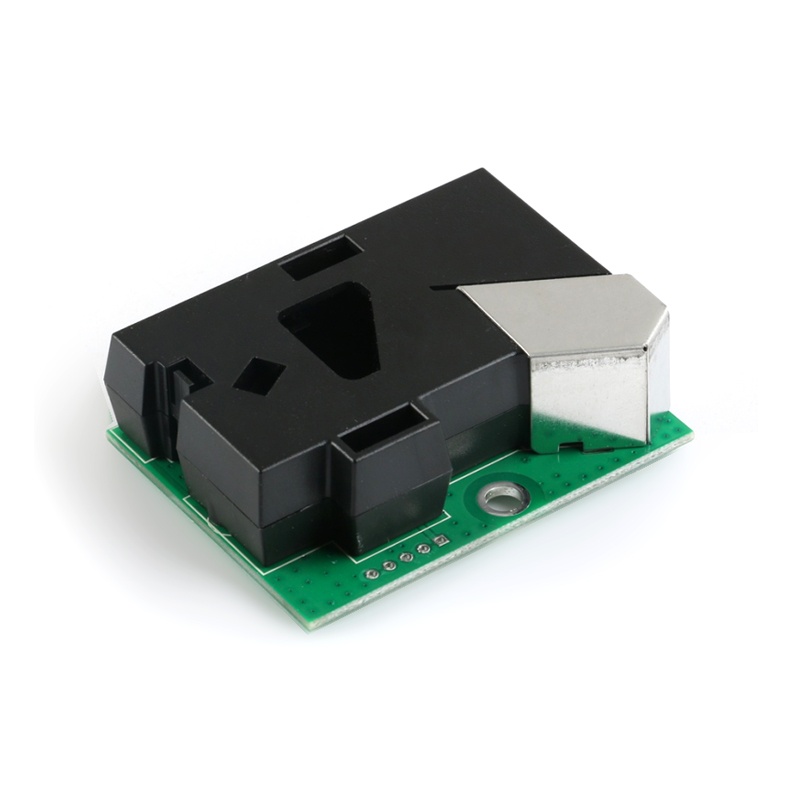

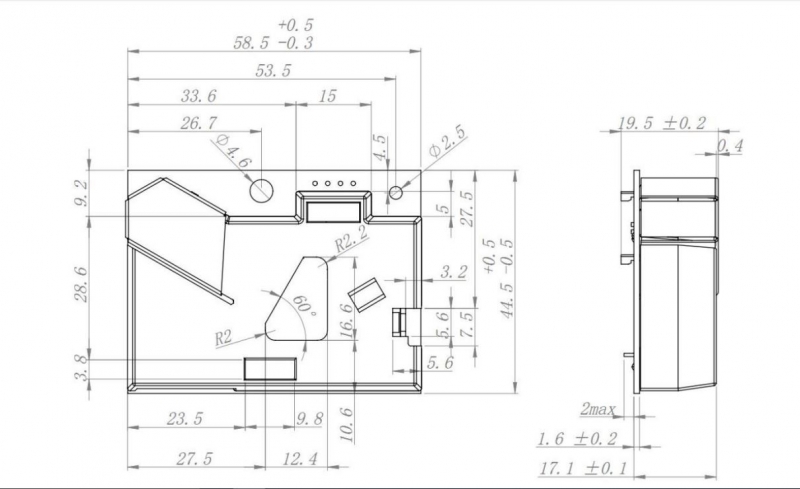

ZPH02 LASER Dust Sensor Dimensions

ZPH02 Dust Sensor Pinout

| Pin | PMW mode | UART mode |

|---|---|---|

| PIN1 | GND | GND |

| PIN2 | NC | TXD |

| PIN3 | VCC | VCC |

| PIN4 | PWM | NC |

| PIN5 | NC | Connects to GND |

Output Signal

| Grade | Output A | Output B | Pollution Grade |

|---|---|---|---|

| 0 | 0V | 0V | Clean |

| 1 | 0V | +5V | Light pollution |

| 2 | +5V | 0V | Moderate pollution |

| 3 | +5V | +5V | Severe pollution |

ZPH02 Precautions

- Installation requirements of Laser Dust Sensor: The sensor must be installed vertically to ensure that the gas path is smooth and avoid contact with organic solvents.

- To ensure smooth detection of gas flow outside the air flow can smoothly into the sensor optical cavity and timely discharge. When applied to the air refresher, the fan inlet and outlet air flow can not affect the stability of the sensor detection gas path, can be installed on the side of the body.

- To avoid light. Dust sensor uses a specific wavelength light LED and visible light cut off the photoelectric sensor to detect dust particles, external light radiation will affect the dust sensor optical signal, it is recommended to use the sponge cover dust sensor center triangle hole , do not block Sensor inlet and outlet.

- .Power supply requirements: Module metal shield and circuit GND connection, should prevent the GND pin access to higher than the human body safe voltage system, should not be applied to the system involving personal safety.

- Clean the lens: the lens needs to be cleaned according to the use of the environment, once about 6 months. When cleaning, use a cotton swab to rinse the surface of the lens, and then wipe the water with another head in time. Do not wipe the lens with organic solvents such as alcohol.